You might be wondering about these types of panels, as how to make them and how to apply skills on them. But it's really simple. Once you give attention in making these types of panels, believe me you are going to be master one day. I have learnt these in 3-4 days. But you are going to lean in a day if you read this blog fully.

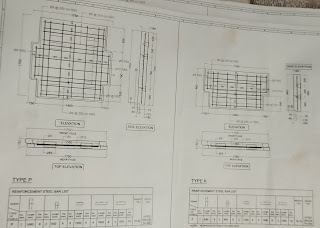

First of all, the main important thing is to understand the BBS. If you understand this BBS then making these type of panels would be easy for you. And to understand this BBS all things are given on the drawing itself. Wait, I will show you.So all these you can see different types of reinforcement for different panels. If you can understand about these reinforcement's, then easily you can make different types of panels. But for that you should have to be proper trained enough and proper skilled enough.

I can give lot of brief description about these. But it will be boring for you. Instead of getting all the knowledge, you clarify yourself, as how you will implement it. Getting knowledge is not enough if you don't implement your skills or utilize it. Because work is same, but way is different for different types of panels and for different site also.

But before explaining all these things, you have to understand first how to make panel casting. If you doesn't know about that, then first look at this blog. After that you will come to know something about panels. Because without casting, nothing you are going to learn. All these will mesmerize your brain.

For panel casting you should be sure enough whether all these are made in proper size or not. Whether all these things will be appropriate or not. Without considering all these, nothing is going to make any difference. So, I think you might have read the previous blog or the link I have given you, and now you come to understand more something about panels.

After making all these panel casting, the very next day you should have to deshutter the molds and keep the panels in a shaded area. So that it be-comes mature and increases it's compressive strength. But regularly take care and keep watering the panels, i.e., curing. So that it increases it's strength and also the water which evaporates from concrete, regains it by curing.

Wait you are blunt, you will understand it by showing some pictures.

|

| This is called deshuttering of panels, which is also known as demolding. |

By doing all these process you are now clear how to make different types of panels. You have learnt about casting of panels. For launching of panels or erection of panels, I will explain that in another blog. First be clear with this, after that we will discuss about erection of panels or how to fit the RE Wall.

Thank You,

Comments

Post a Comment

Please do not enter any spam comment.